Standing at the crossroads between ordering a single sample and committing to a full production run frequently enough feels like choosing a path without a map. Both options promise rewards-one offers a swift, low-risk preview; the other unlocks scale and lower unit costs-but they come with different timelines, costs, and uncertainties that can reshape a projectS outcome.

This article cuts through the jargon to lay out the practical differences between sample and bulk orders. You’ll get a clear look at costs, lead times, quality control, minimum order quantities, and common pitfalls so you can weigh risk against opportunity and choose the approach that fits your product, budget, and timeline.

Table of Contents

- Understanding Sample Orders Versus Bulk Purchases: When Each Option Makes Sense and Why

- Testing Samples Effectively: Key Evaluation Metrics, Real World checks, and Red Flags to Watch

- Negotiating Terms with Suppliers: Price, Lead Time, MOQ, and Sample Allowances Explained

- Ensuring Quality at Scale: Inspection Protocols, Lab Testing, and Third-Party Verification

- Managing Risk and Scaling Up: Returns, Contingency Plans, and Gradual Order increases

- Q&A

- In Retrospect

Understanding Sample Orders Versus Bulk Purchases: When Each Option Makes Sense and Why

Deciding between ordering samples or committing to a full production run is often the difference between a smart experiment and an expensive surprise. Samples let you validate fit, finish, and functionality before the money multiplies; bulk buys reward confidence with lower unit costs and stable supply. Consider the unknowns: new supplier, unproven design, or a novel market, and favor sampling. When specifications are locked, demand is predictable, and cash flow supports inventory, bulk becomes the pragmatic choice.

- Choose samples when: testing quality, checking packaging, verifying lead times, or piloting a new SKU.

- Choose bulk when: demand forecasts are reliable, economies of scalelead to lower prices, and storage/logistics are in place.

- Hybrid approach: small initial bulk orders after sample approval can balance risk and price.

| Factor | Sample | Bulk |

|---|---|---|

| Unit Cost | High | Low |

| Risk | Low | Higher (if assumptions fail) |

| Lead Time | short | Long |

Tip: Pair sample testing with a clear acceptance checklist so your bulk order delivers what the sample promised.

Testing Samples Effectively: Key Evaluation Metrics, Real World checks, and Red Flags to Watch

When a sample arrives, treat it like a live audition: measure performance, aesthetics, and compliance under conditions that mimic your customers’ experience. Focus on functional metrics (does it work every time?), dimensional tolerances (does it fit or stack as specified?), and appearance (color, finish, and packaging integrity). Quick, repeatable checks you can run in-house include:

- Stress & fatigue tests – repeated usage or load cycles to spot early failure.

- Fit and tolerance checks – assembly or interchangeability with mating parts.

- Finish and colorfastness - rub tests, sunlight exposure, and wash cycles.

- Safety and chemical screening – smell, obvious residues, and basic compliance marks.

- Packaging & transit simulation – drop tests and moisture exposure.

Use a short, consistent checklist to rate each sample and flag anomalies immediately. The table below is a compact cheat-sheet you can paste into your QA workflow or supplier email when discussing failures:

| Metric | Quick Check | Red Flag |

|---|---|---|

| Durability | Cycle a function 50-100 times | Cracks, loosened parts, and a performance drop |

| Dimensions | Measure with calipers vs. spec | Out-of-tolerance by spec margin |

| Appearance | Visual + rub/color tests | Uneven dye, chips, inconsistent finish |

| Packaging | Drop/stack test, seal check | Torn boxes, crushed items, loose parts |

Document everything with photos, short videos, and a one-line verdict (pass/warn/fail). If multiple red flags appear, negotiate corrections or new samples before scaling to bulk - it’s far cheaper to fix at the sample stage than to manage a full production recall.

Negotiating Terms with Suppliers: Price, Lead Time, MOQ, and Sample Allowances Explained

Think of negotiation as a trade-off map: every concession on price often costs you in lead time or requires a higher MOQ. Start with a clear priority-do you need speed, low unit cost, or low upfront risk? Use specific tactics like asking for tiered pricing, requesting a sample allowance that can be credited to the first bulk order, and proposing longer lead times in exchange for lower costs. Put agreed terms in writing (including shipping responsibility, inspection criteria, and penalties for missed dates), so a verbal promise doesn’t become a surprise later. Practical questions to open with suppliers:

- Can you offer a sample credit if I place a bulk order?

- What volume breaks trigger discounts?

- How flexible is your MOQ if I mix SKUs?

- What lead time reduction options exist and at what cost?

Negotiation is a series of small agreements that add up to be willing to mix solutions (e.g., smaller MOQ + higher per-unit price or longer lead time + a lower rate). Below is a quick cheat sheet to compare the common levers and what to offer or accept:

| Term | Typical Ask | Quick Negotiation Tip |

|---|---|---|

| Price | Tiered discounts at volume | offer a forecast or partial prepayment for better rates |

| Lead Time | Faster turnaround for a premium | Accept split shipments to balance speed and cost |

| MOQ | Lower initial quantity for testing | Combine SKUs or agree to rolling orders to meet MOQ |

| Sample Allowance | Free or credited against the first order | Specify tolerances and who pays return shipping |

Ensuring Quality at Scale: Inspection Protocols, Lab Testing, and Third-Party Verification

To keep quality consistent when you move from a sample to a full production run, establish clear, repeatable inspection protocols that every partner understands. Start with a written sampling plan and Acceptance Quality Limit (AQL), and make sure inspectors have checklists for critical-to-quality attributes. Typical checkpoints include:

- Incoming materials: verify specs on batches before production

- Inline checks: dimension, color, and function checkpoints during manufacturing

- Pre-shipment inspection: full visual and functional review of finished goods

Lab testing should be used strategically: not every order needs exhaustive testing, but certain risks demand it-chemical safety, flammability, electronics certification, or durability. Use accredited laboratories and require written reports with traceable methods. Common lab verifications include:

- Materials analysis: composition, contaminants, and performance

- Safety testing: CE, FCC, RoHS, or regional regulatory checks

- Performance/durability: lifecycle, wear, and stress tests

For ultimate assurance, engage third-party verification: self-reliant factory audits, chain-of-custody documentation, and certificates from recognized bodies convert subjective trust into objective evidence. A short reference table helps buyers choose the right layer of verification:

| Verifier | When to Use | Primary Benefit |

|---|---|---|

| Independent lab | High-risk materials or regulatory products | Objective compliance data |

| Third-party inspector | Large bulk orders, pre-shipment | Consistent, unbiased QC checks |

| Certification body | Market entry or shelf-label requirements | Recognized credentials for buyers |

Managing Risk and Scaling Up: Returns, Contingency Plans, and Gradual Order Increases

Think of returns and refunds as a built‑in safety valve rather than an afterthought. Define a clear return window, specify acceptable reasons, and require photographic or video evidence to speed claims. Negotiate practical restocking terms and consider a small holdback or milestone payment until a third‑party inspection confirms acceptance-this distributes risk without halting production. For high‑value shipments, add transit insurance and a documented RMA workflow so every party knows where responsibility begins and ends.

- Clear return window and documented reasons

- Pre‑shipment inspection or third‑party QC

- Transit insurance for loss/damage

- Holdback/milestone payments to protect buyer cash flow

- RMA & evidence requirements to streamline claims

Scale deliberately: start with a pilot batch and grow through staggered increases tied to KPIs like defect rate and on‑time delivery. Maintain a written contingency plan that names a backup supplier, sets maximum lead times, and defines when to trigger safety stock orders. Use short cadence reviews after each ramp phase so you can adapt payment terms, packaging specs, or logistics before committing to full production.

| order Stage | Typical Size | Key Controls |

|---|---|---|

| Sample | 1-5 units | Approve fit, finish, specs |

| Pilot | 5-100 units | QC checks, transit test |

| Bulk | 100% target | Full QA, backup supplier |

Q&A

From Kabeier | Custom Baby & Children’s Clothing Manufacturer

Q: What’s the difference between a sample order and a bulk order?

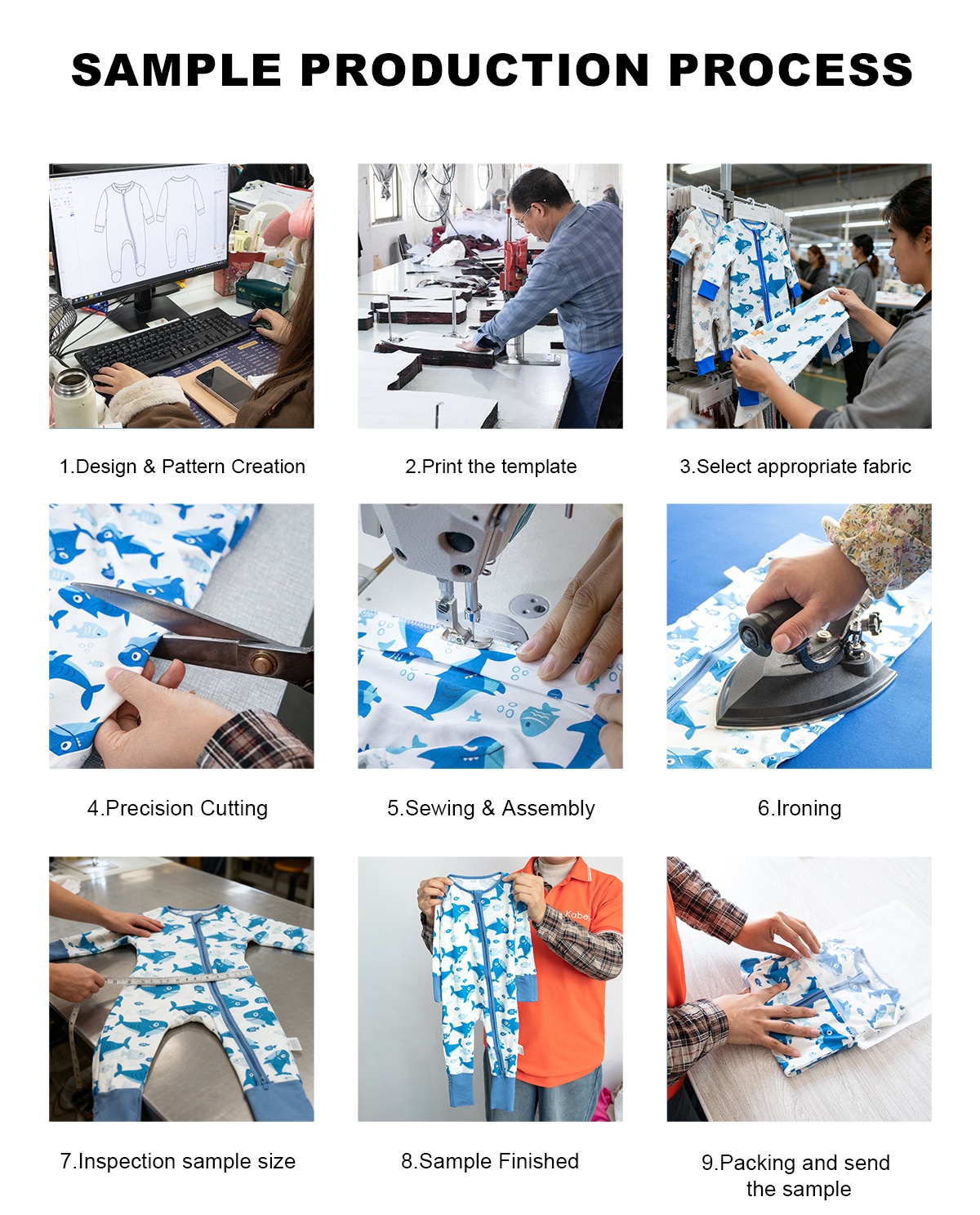

A: At Kabeier, a sample order usually means one or a few pieces made to verify design, hand-smocking quality, fit, fabric, and overall finish. A bulk order is the full production run intended for retail or wholesale. We often describe samples as the “dress rehearsal” and bulk production as the “opening night.”

Q: Why should I order samples before committing to bulk?

A: Samples allow you to see the real craftsmanship—especially important for hand-smocked dresses. They help identify potential issues with sizing, fabric hand feel, smocking density, embroidery placement, or color tone before large-scale production. Sampling significantly reduces risk and avoids costly revisions later.

Q: When is it acceptable to skip samples?

A: Skipping samples may work if you’ve produced the same style with Kabeier before, the design is unchanged, or timelines are extremely tight. Even then, we usually recommend at least a pre-production sample to confirm consistency, especially for handwork items.

Q: How do costs compare between sample and bulk orders?

A: Samples cost more per unit because hand smocking setup, pattern work, and skilled labor are applied to a small quantity. In bulk orders, these costs are spread across production, resulting in a lower per-unit price. Sample fees, shipping, and possible revisions should always be factored into the total cost.

Q: How do lead times differ?

A: Sample production at Kabeier typically takes a few days to a few weeks, depending on design complexity and hand-smocking details. Bulk production takes longer due to fabric sourcing, scheduling, and quality control. Shipping and customs timelines apply to both.

Q: What is MOQ, and how does it affect the decision?

A: MOQ (Minimum Order Quantity) is the lowest quantity we can efficiently produce. For custom hand-smocked dresses, MOQs reflect the labor involved. We often help clients balance MOQ by adjusting unit pricing, simplifying details, or splitting production into stages.

Q: How should I evaluate the quality of a sample?

A: Review fabric quality, measurements, smocking neatness, stitch consistency, comfort, and overall appearance. At Kabeier, we encourage clients to compare samples directly against approved specs and confirm that the hand smocking matches expectations.

Q: What should I do if a sample isn’t right?

A: Share clear feedback—photos, measurements, and notes. Our team will revise the pattern or hand-smocking details and provide an updated sample. Once approved, all changes are documented before bulk production begins.

Q: How do customization and design changes affect sampling and bulk?

A: The more customized the design, the more important sampling becomes. Changes to smocking patterns, embroidery, or fabric often require new development. Kabeier always recommends locking final specs only after sample approval.

Q: What are common payment terms for samples and bulk orders?

A: Samples are usually paid in full upfront. Bulk orders typically follow a deposit + balance structure. We work with clients to agree on terms that balance trust, production scheduling, and risk.

Q: How should I handle shipping for samples vs. bulk?

A: Samples are usually shipped via express courier for speed. Bulk orders are shipped by sea or air, depending on budget and delivery timelines. Kabeier clearly defines Incoterms and packaging standards before shipment.

Q: What legal or contractual protections should I have before bulk ordering?

A: Clear documentation is essential—approved samples, specification sheets, delivery schedules, quality standards, and inspection terms. We support transparent agreements to protect both sides.

Q: How can I reduce the risk of supplier mismatch or fraud?

A: Work with experienced manufacturers, request real production photos, start with samples, and keep communication documented. Kabeier welcomes audits, inspections, and long-term partnerships built on trust.

Q: Are there environmental or ethical issues to consider?

A: Yes. Sampling and rework can increase waste, so careful planning matters. Kabeier prioritizes responsible labor practices, controlled production runs, and thoughtful material sourcing.

Q: How do I decide when to move from sample to bulk?

A: Ask yourself:

-

Does the sample meet all approved specs?

-

Are the smocking quality and fit consistent?

-

Are the costs workable at bulk pricing?

-

Is the demand confirmed?

If yes, bulk production can move forward—often in staged quantities.

Q: Practical tips for a smooth sample-to-bulk transition

A:

-

Always approve a final sample in writing

-

Confirm all hand smocking and fabric details

-

Use pre-production samples for complex designs

-

Keep communication clear and documented

-

Allow buffer time for hand-crafted production

Quick checklist before placing a bulk order with Kabeier:

-

Approved sample signed off

-

Final specs and measurements confirmed

-

MOQ, pricing, and payment terms agreed

-

Production and delivery timeline set

-

Inspection and shipping terms clarified

In Retrospect

Choosing between a sample and a bulk order doesn’t have to be a leap of faith – it’s a step in a process. Samples give you a controlled glimpse of quality, fit, and finish; bulk orders deliver scale and unit savings. Weigh cost, timing, risk tolerance, and your capacity to manage defects or returns, and let those realities guide your choice. Think of samples as your compass and bulk as the map: one helps you orient, the other takes you the distance. When in doubt, test the route – request a sample, clarify specifications, and agree on inspection and remedy terms before committing to volume. For many buyers, a phased approach or staggered orders strikes the best balance between certainty and efficiency.

Informed decisions come from clear expectations, open supplier communication, and a practical assessment of your business needs. Armed with those elements, you can pick the path that fits your goals – whether you’re validating a new product or scaling a proven winner.